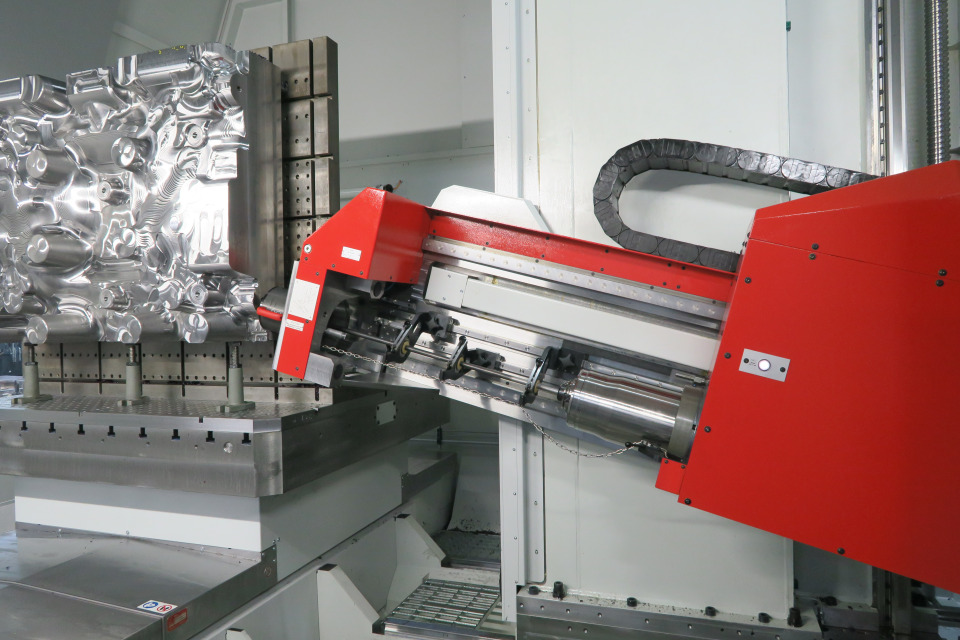

By investing in SAMAG’s deep-hole boring facility, KRÄMER+GREBE is filling an important gap in the process of manufacturing contoured parts for die-casting moulds and inorganic core boxes. Our consistent objective is to continue to improve production methods both qualitatively and quantitatively, while also achieving the highest levels of precision and creating our own unique terminology, without ignoring rationality and universality.

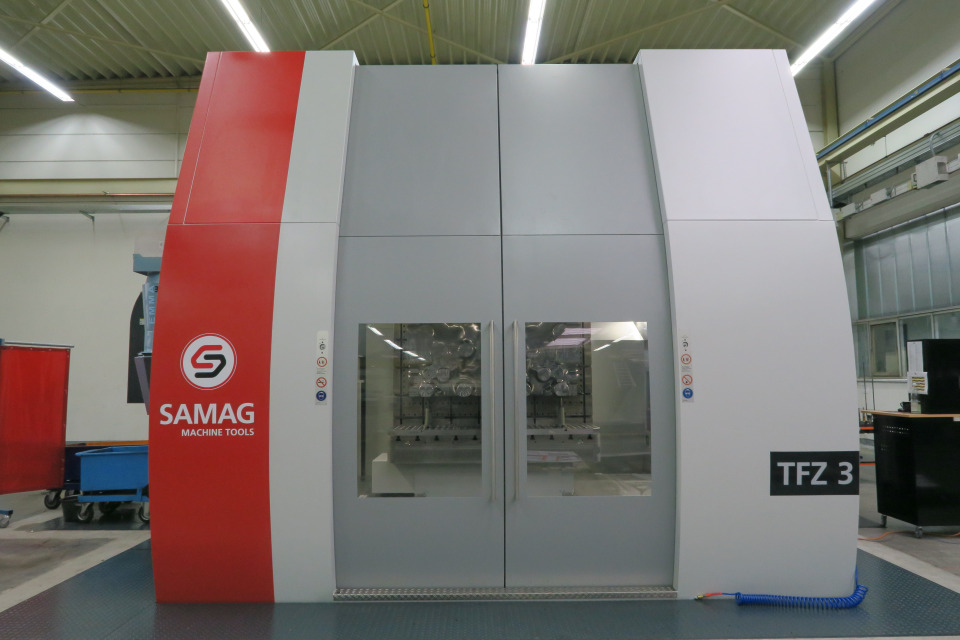

The SAMAG TFZ3, with its technical specifications, achieves maximum bore depths ranging from 1,800 mm to 40 mm in one go, thereby meeting all the requirements for the tempering systems of complex components.

Moreover, it also boasts a replaceable milling head designed for horizontal pre-machining which has a milling capacity of 475 cm3/min. Due to the range of motion, X/Y 2,000 mm/1,650 mm, there is no limit to how large the contour components can be. Thanks to the increased table load of 20t, die-casting moulds can be easily processed.

Th 3D CAM system GIBcam-DRILL was selected as a CAM programming system for creating NC drilling programs. This makes it possible to easily program and execute bore holes even if they intersect or occur multiple times.

The company is now fully equipped to create high-tech moulds for any casting process and to tackle the technical challenges that come with modern lightweight casting components.