Mannheim – Biedenkopf Wallau July 21, 2018. There is always a first time, just as recently happened in the history of the foundry Mannheim of the longtime client Daimler AG. In order to meet the highest quality criteria and at the same time produce very efficiently, for the first time a completely new tool concept was developed in cooperation with a development partner instead of building on a tried and tested one. The tool should serve the new cylinder head core production of the 10.7L to 15.6L heavy-duty engine platform (HDEP) engine generation. Together the partners have now created a double-beam core mould which not only sets new standards in design and quality but at the same time significantly reduces the total cost of ownership (TCO).

Since decades already the leading companies have been working together on prototype developments. And even though core mould tools are always regarded as a ‘matter of course’, they are very much essential for the manufacturing of innovative products with qualitative excellence. Especially when it comes to quality standards, compromises are not an option – it is only “The best or nothing” according to the in-house motto. In order to fulfil these challenges of toolmaking, the company was looking for a partner with whom it could independently develop an innovative tool concept that would meet all of the company’s own standards and the highest demands in subsequent production. As a long-standing trusted partner for the tool production of cylinder heads, among other things, eventually, the mould and toolmaker Krämer+Grebe fully convinced. Particularly due to their maximum flexibility, the use of the latest technologies, simulation and production methods, an extremely tight timeline and a highly demanding development loop, Krämer+Grebe was the perfect partner for a development project of this scale.

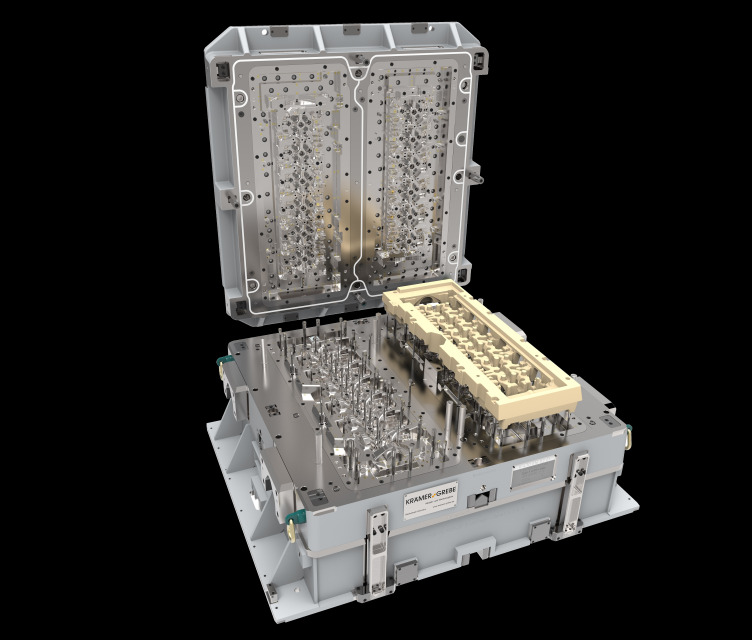

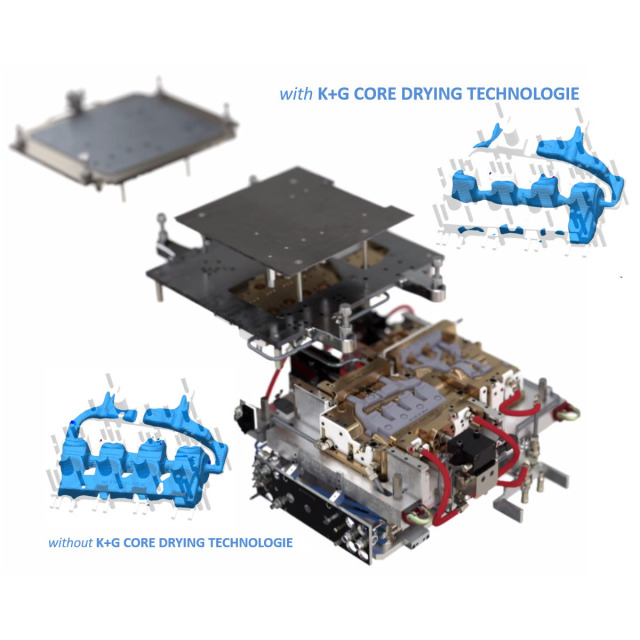

While in 2015 first considerations were made, a year later already, in late summer 2016, the go-ahead was given for the joint project to develop a completely new and more efficient tool concept. The starting point was the existing single-core cylinder head mould. From there special features of the new concept should include double engraving, ease of maintenance, functionality and robustness. By means of FEM calculations, in particular, the latter could be guaranteed. A specific focus during the tool design was also placed on stress reduction and minimisation of deflection, as well as the analysis of various load cases, such as shooting head and load carrier. The highlights of the entire development process were comprehensive core process simulations in several development loops, which made it possible to redefine bullet holes, ejection and venting at an early stage of the process. Overall, the tool concept is now optimised in such a way that it has an extremely positive effect on maintenance, lifetime and repairs. This is of great importance for the new concept, as it extends the production cycles, significantly reduces the amount of amine required as well as the original tool weight by 600kg.

An equally faithful process companion throughout the entire concept development and of high importance for the final construction was the decisive criterion of minimising the TCO. According to Katrin Grebe, managing director of Krämer+Grebe, an essential point within every development process, still a truly holistic and early focus is often considered too rarely. Therefore, among other things, also the philosophy of using standard parts in such developments is crucial for its success. This represents not only a considerable cost factor but also increases the ease of maintenance.

Due to the overall complexity and amount of demands towards the new tool concept, hence it is no surprise, that the cooperation between the two companies built on a maximum level of trust and continuous exchange of experience. As a result, for example, the tool was directly adapted to the “State of Art Technology” in order to achieve the best possible production performance.

On July 24, 2018, the innovative double girder core mould was officially handed over to the foundry in Mannheim and therewith completed to the fullest satisfaction of both companies. But what significance does this step actually have in retrospect for the companies and the industry? Together they not only created an innovative and efficient core mould for the HDEP cylinder heads, but have taken it a further and far-ahead step towards a technological future. All of this would of course not have been possible without the valuable exchange of experience with Krämer+Grebe. A partner that completely convinced throughout the process and was once again able to prove the unique performance they accomplish as a development partner. And eventually what counts the most is: only together we are strong. Thus it was possible for both parties to develop a tool concept that not only makes every foundry heart beat faster but above all sets new standards. We can therefore already be excited about future projects of this development partnership.