A process newly developed and patented by KRÄMER+GREBE can be used in the following cases for better core-drying performance. Currently, casting foundries mainly employ the polyurethane cold-box process to manufacture cores while inorganic core-making processes are gaining popularity. During the cold-box process, the reaction and the accelerated curing of the core are set off through the addition of a catalyst mixed with a carrier medium.

In inorganic core-making, however, this curing process is replaced by heating and purging with hot air, which causes water to evaporate and moisture to escape from the core box. It is a more complex and time-consuming process that is related to sand casting and curing, and is therefore subject to certain restrictions. This means that there are limitations on void spaces and geometry during inorganic core-making processes. Nevertheless, a compromise can be found between core filling and core curing.

Depending on the core geometry, an analysis can also show that the K+G core drying technology produces significant cycle time improvements in the cold box process.

The patented Core-Drying Technology is integrated into the core box and can be fitted in new or existing moulding tools.

News

This year’s WFO Technical Forum, held from 18 to 20 September 2019 in Portorož, Slovenia, saw KRÄMER+GREBE participate in the event as an exhibitor for the first time. With more than 400 participants from 27 countries, the Forum achieved a record number and provided an international platform for the company to present its work and its latest technology, as well as network with new and existing contacts.

On the last day of the event, the speaker from KRÄMER+GREBE, Jan Titze, gave a talk with the title “With sensors and actuators to autonomous foundry tools”. He explored casting process optimisation in detail through tooling with additional sensor technology and an integrated data management system, as well as greater casting process control flexibility using actuator technology. Finally, the talk included a brief look at the possibilities for individual and optimised production of cast parts in the future if these two areas of potential, sensor technology and actuator technology in the tool, are combined.

14.08.2019

GIFA 2019

After five eventful trade fair days, GIFA came to a successful conclusion on Saturday 29th June.

A team of experts from KRÄMER+GREBE was also present at the event and was able to hold many interesting discussions and make new contacts.

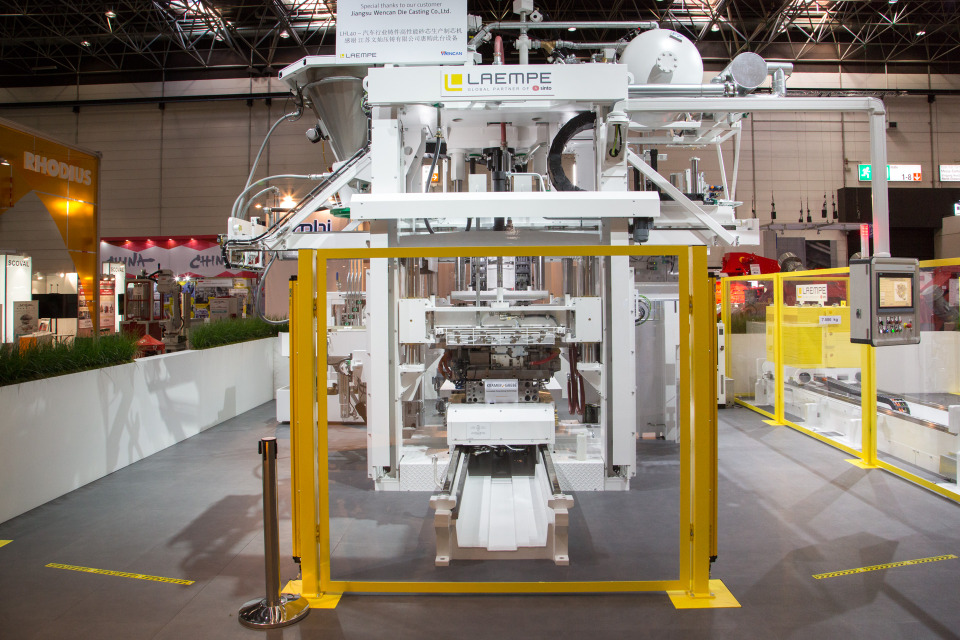

At the Laempe Mössner Sinto GmbH stand, the K+G team discussed, for example, the advantages of its patented core drying technology using a core box equipped with the technology with trade fair visitors who were interested in finding out about this.

In addition, two speakers from KRÄMER+GREBE gave a presentation on state-of-the-art methods for 3D measurement technology in product development during a break-out session hosted by GOM.

KRÄMER+GREBE would like to thank all its customers and visitors for their interest and the great discussions. We would also like to express our thanks to the team at Laempe Mössner Sinto GmbH for providing active support at the stand and GOM for the cooperation on the topic of process optimisation.