100 Years KRÄMER+GREBE

WOW, that’s Kraemer+Grebe Spirit – 100 years of machine and tool development of the Krämer+Grebe family were duly celebrated. This…

The comprehensive range of services offered by KRÄMER+GREBE makes us a market leader in tool solutions for all casting methods. As well as the manufacturing and maintenance of outstandingly high-quality and reliable tools, we are there to support you with tool and casting process-related tasks, from the initial idea through to series production. As a development partner our efforts are directed towards the realisation of groundbreaking innovations. For our international customers we are the first choice for developing highly innovative and complex tool solutions, including those related to new downsizing challenges or to electromobility.

From nominal data structure and component development, through tool layout and concept development, to parametrical tool construction: KRÄMER+GREBE’s extensively trained specialists are familiar with all casting processes and support our customers through all development phases, from the idea to series production. The more complex the casting concepts are, the more thorough is the exchange that takes place with customers and partners. Thanks to our ‘simultaneous engineering’ approach, the development process is significantly improved, saving time and exploiting valuable synergies. And because of our extensive know-how, we are the first choice as a developer, particularly for new challenges such as electromobility or selecting the right casting process.

In combination with our market-leading services, we can provide mobile service teams. In many cases our tool specialists can be on your site within a response time of 24 hours to support you in the event of unforeseen problems, maintenance works and repairs.

Additionally, we offer running-in and process support with delivery of our products in order to ensure undisturbed production and the outstanding level of quality that is expected of KRÄMER+GREBE.

At KRÄMER+GREBE we offer individual maintenance and repair plans. Our logistics network enable us to provide a rapid, flexible response to maintenance and repair tasks, in our own state-of-the art facility with furnace for heat treatment. Unplanned emergencies can be resolved in short response and implementation times with our flexible work schedules. Additionally, our mobile service teams can also perform maintenance and repairs on our customers’ premises.

In our tool and process optimisation, the more then 100 years of experience and intensive personnel development work of KRÄMER+GREBE is particularly evident. Our specialists are familiar with all tool solutions for the most diverse metal casting processes. Thanks to our know-how and knowledge management system, experience is passed between the generations and across divisional boundaries. In combination with the latest analysis and simulation tools, we advise our customers on the optimisation of tools and processes. We perform process analyses and develop technical concepts, functional specifications and optimisation proposals on costs, quality and not least on sustainability and the environment, so that your wishes can be realised in the best possible way.

The market-leading full-services offered by KRÄMER+GREBE for tool solutions for all casting processes is further extended with the following services: quality assurance and delivery and transport.

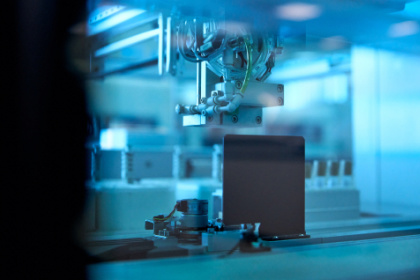

When it comes to developing and manufacturing high-tech tools and model equipment, KRÄMER+GREBE is the specialist. The company develops concepts for foundry requirements and for complete systems and tools. For this, close and professional collaboration with the customer is our highest priority.

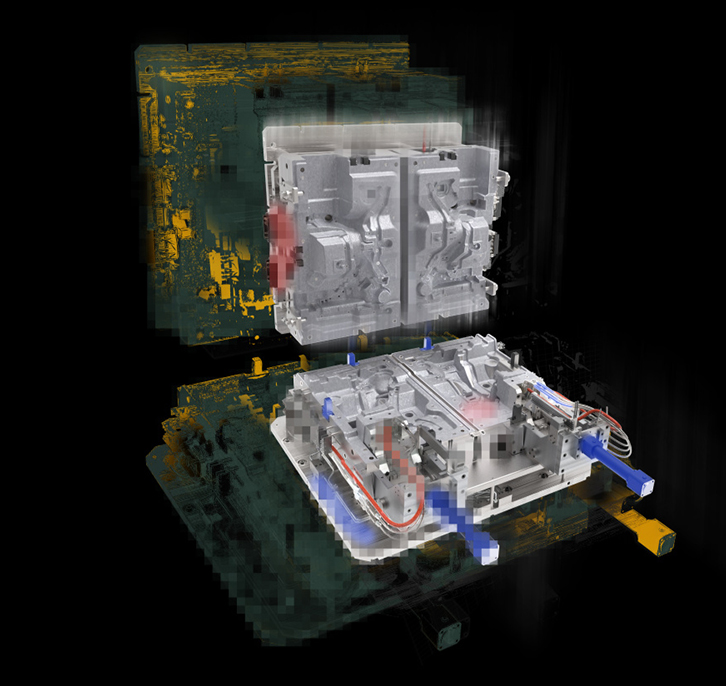

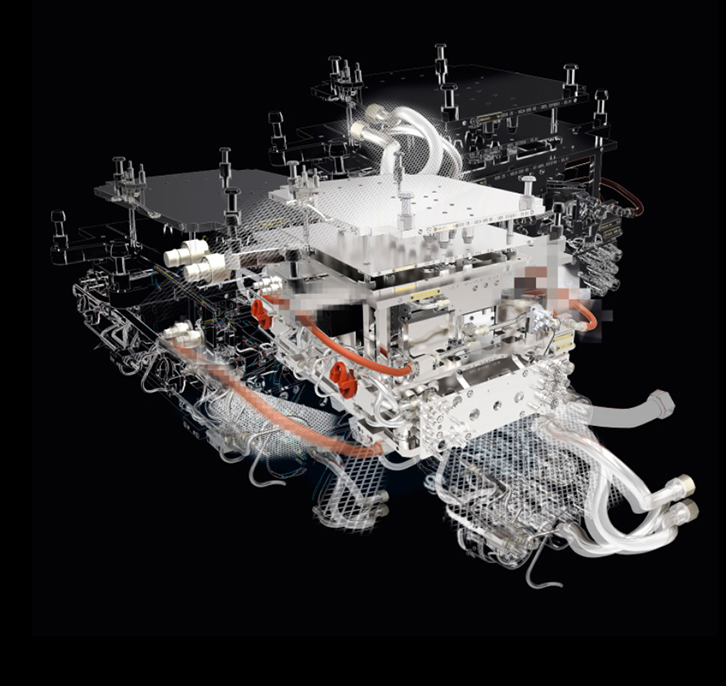

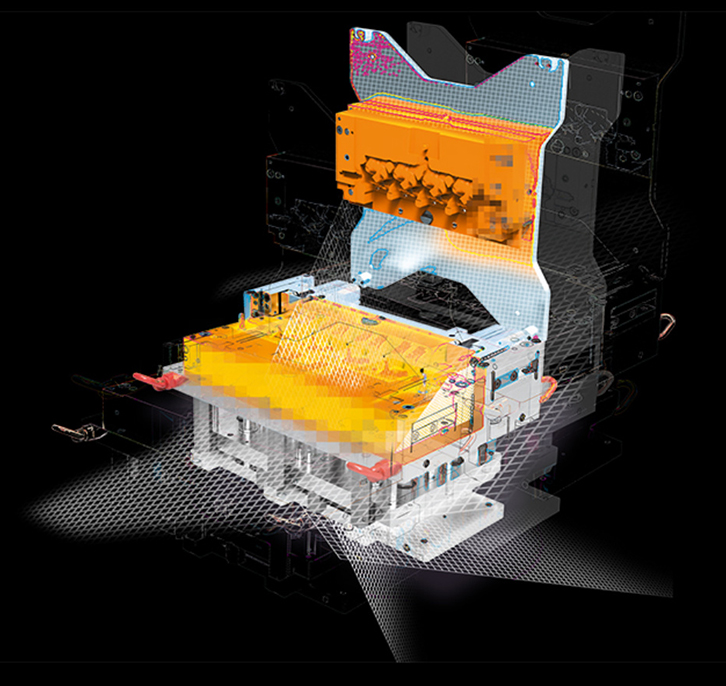

For castings subject to high stresses and with complex geometries, that is, with a high degree of freedom in design, a fine structure and good mechanical properties, it is not uncommon for permanent-mould-casting to be the first choice. As one of only a few tool makers, at KRÄMER+GREBE we are capable of meeting the widest range of requirements for all types of permanent-moulds. We are in the best position to offer the highest level of dimensional accuracy and optimal functionality for permanent-moulds in high-quality steel. We use our deep resources of experience and expertise to design and manufacture gravity and low-pressure moulds of all types with local deployment of special materials, high-performance cooling systems and local cooling, with temperature control and complex slider techniques, including in intelligent monocoque structures. Our moulds – with or without their own sand cores are based on ideal designs. The 100% shapable steel moulds meet both economic and functional requirements.

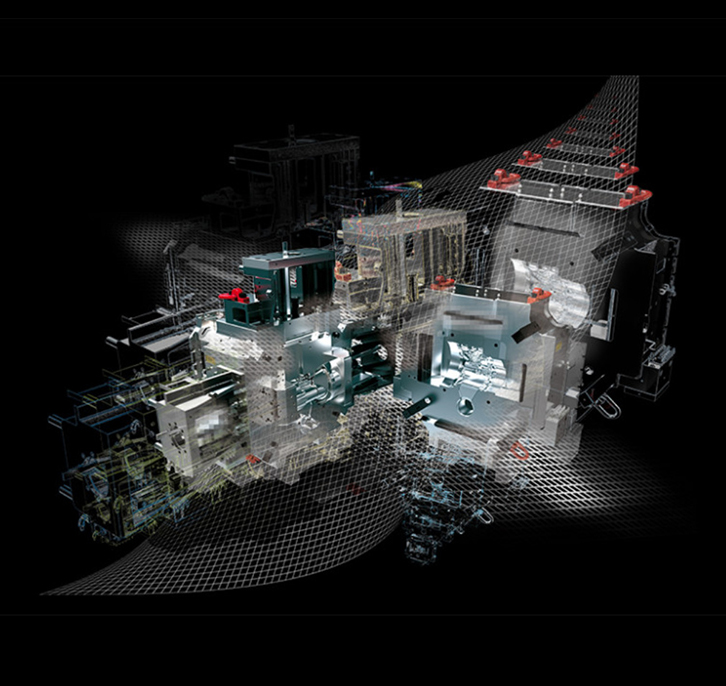

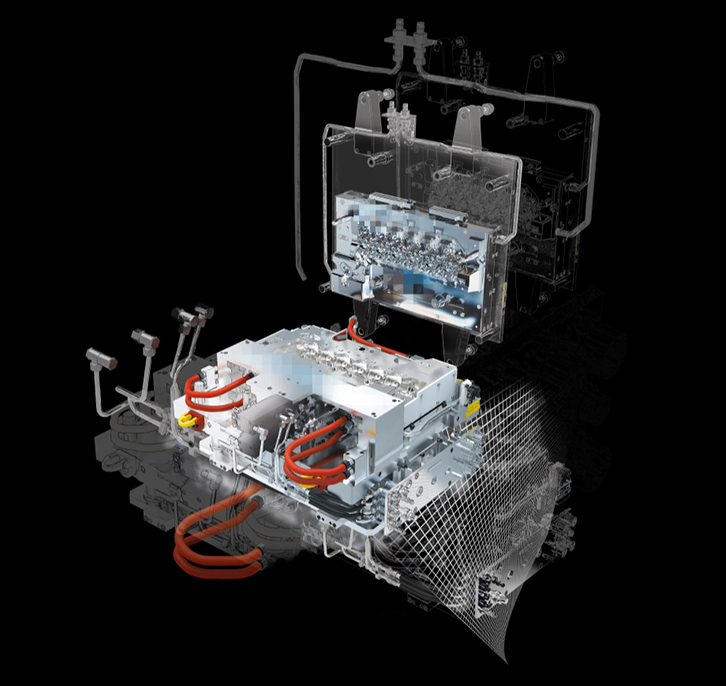

From design through engineering to production, we offer the entire process for high-pressure dies suitable for a wide variety of aluminium and magnesium castings. The modern equipment is also suitable for dies of the current trend in the field of mega and giga casting. Whether part of a powertrain or for large structural and chassis components, high quality, close tolerances and absolute precision are decisive for high-pressure dies. We will therefore support you from the development and design stages with filling and solidification simulations for the sprue and spillover positioning. This involves our modern equipment, such as the latest 5-axis simultaneous machining centres including workpiece and tool changers, which assures high-precision results. A spotting press or a chamber furnace for heat-treating the mould inserts and for the maintenance and repair service that also forms part of our services spectrum, complete our range of offerings.

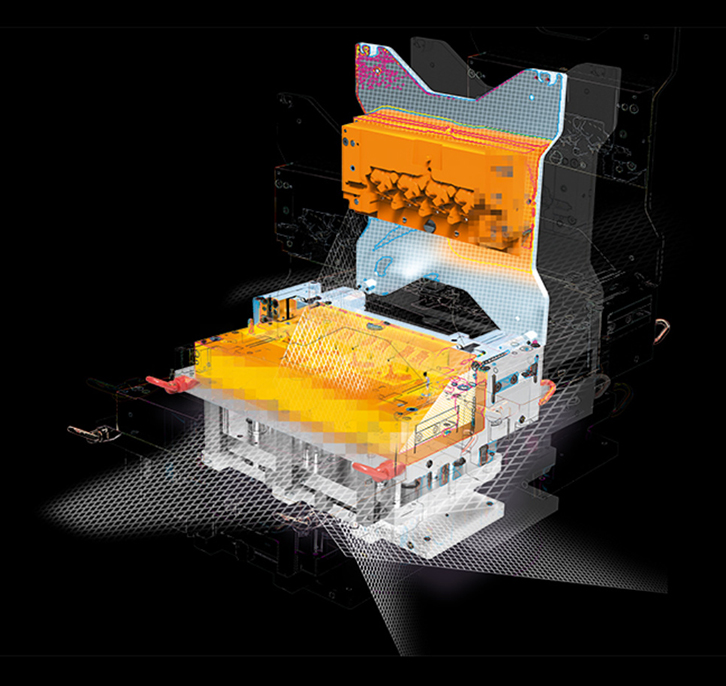

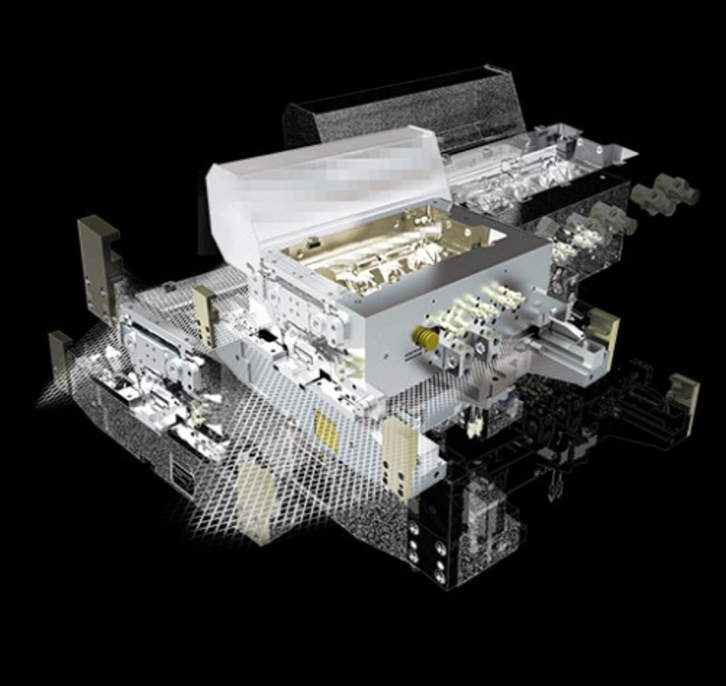

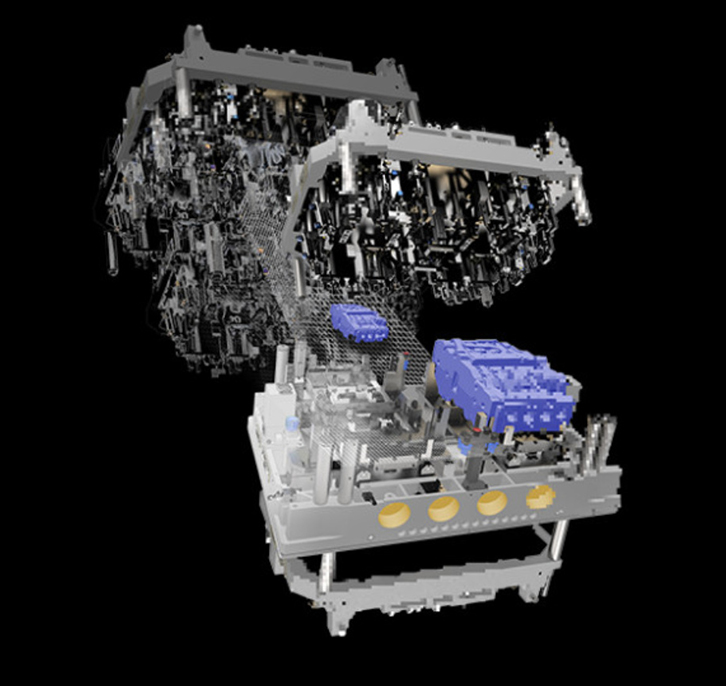

KRÄMER+GREBE designs and manufactures patterns and core box tooling for small and large production series in various materials, complete with all technical casting and venting details. We offer complete tools for your core shooting machine suitable for all core production techniques. We produce individual, tailored tools to your exact requirements with all necessary accessories and to the highest standard of quality as core masks, for core package and green sand processes.

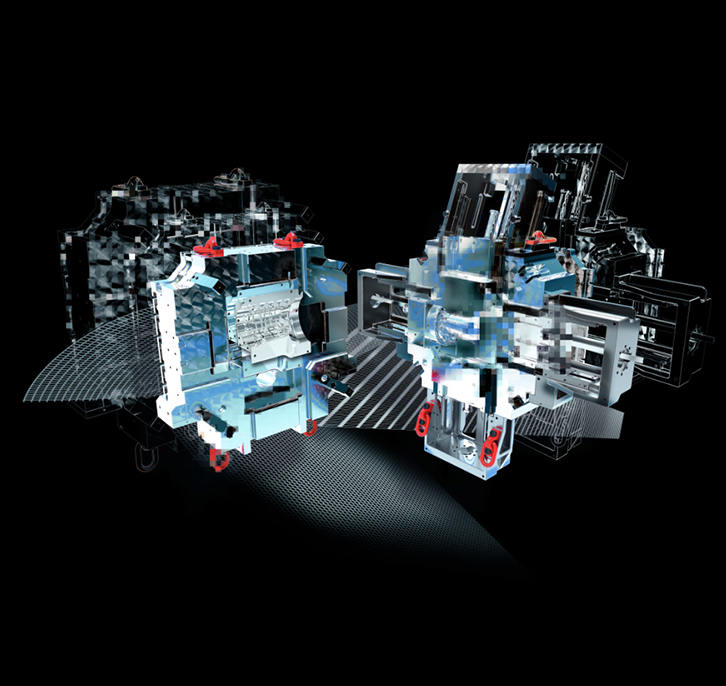

A focus at KRÄMER+GREBE is the development of extremely high-quality tools and complete model equipment. As a direct development partner, a team of our outstanding specialists designs and manufactures complete systems of equipment for foundry use. Complex casting concepts are developed in close exchange with customers and partners; simultaneous engineering harnesses synergies and saves time.

Tailored solutions for every tricky challenge: with each of the many demanding orders that it fulfils, the employees of KRÄMER+GREBE further deepen their area of specialisation. This knowledge is then applied systematically to ensure optimal production processes and perfectly suited complete solutions for handling, control, adjustment, mechanisation and automation.

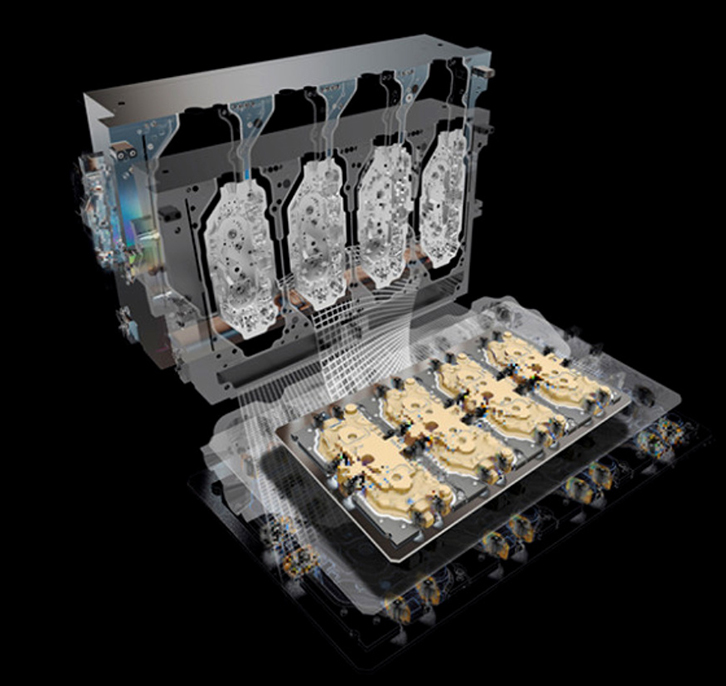

A process newly developed and patented by KRÄMER+GREBE can be used in the following cases for better core-drying performance. Currently, casting foundries mainly employ the polyurethane cold-box process to manufacture cores while inorganic core-making processes are gaining popularity. During the cold-box process, the reaction and the accelerated curing of the core are set off through the addition of a catalyst mixed with a carrier medium.

As one of the market leaders for tool solutions for all casting processes, we have a constant and varied need for materials, products and services. The conviction that the long-term success of our company is also based on cooperation with strong partners gives us the incentive to share our commitment to quality and innovation with you every day.

WOW, that’s Kraemer+Grebe Spirit – 100 years of machine and tool development of the Krämer+Grebe family were duly celebrated. This…

We are very happy about the compliment from the IHK! Praise to everyone who gives their best for the success…

From February 12th – 13th, 2020, the Formstoff-Forum took place for the third time in Munich. The aim of this…

A process newly developed and patented by KRÄMER+GREBE can be used in the following cases for better core-drying performance. Currently,…

This year’s WFO Technical Forum, held from 18 to 20 September 2019 in Portorož, Slovenia, saw KRÄMER+GREBE participate in the…