WOW, that’s Kraemer+Grebe Spirit – 100 years of machine and tool development of the Krämer+Grebe family were duly celebrated.

This year we look back on a successful century. On 02.09. we celebrated this anniversary with our great team. Our goal: to say thank you for a successful 100 years together!

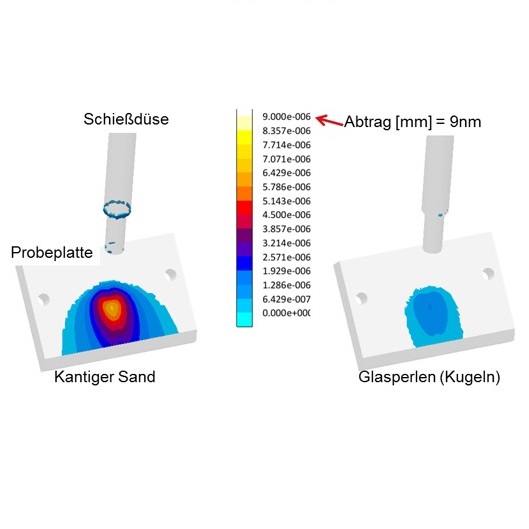

We have always put a lot of emphasis on being ahead of the game – in topics related to sustainability and social issues, and above all: how can we generate even more quality for our customers and the environment. In addition, we have been able to bring sustainability and affordability together – through resource-saving and economical product innovations. Today, we look back together and can say: It worked out great!

Of course, all this is only possible with a strong team. With a size of around 130 employees, which makes us incredibly proud.

A huge THANK YOU to everyone who has made and continues to make these 100 years a success story all along the line.

And now we look forward to another such successful future!