In our tool and process optimisation, the more then 100 years of experience and intensive personnel development work of KRÄMER+GREBE is particularly evident. Our specialists are familiar with all tool solutions for the most diverse metal casting processes. Thanks to our know-how and knowledge management system, experience is passed between the generations and across divisional boundaries. In combination with the latest analysis and simulation tools, we advise our customers on the optimisation of tools and processes. We perform process analyses and develop technical concepts, functional specifications and optimisation proposals on costs, quality and not least on sustainability and the environment, so that your wishes can be realised in the best possible way.

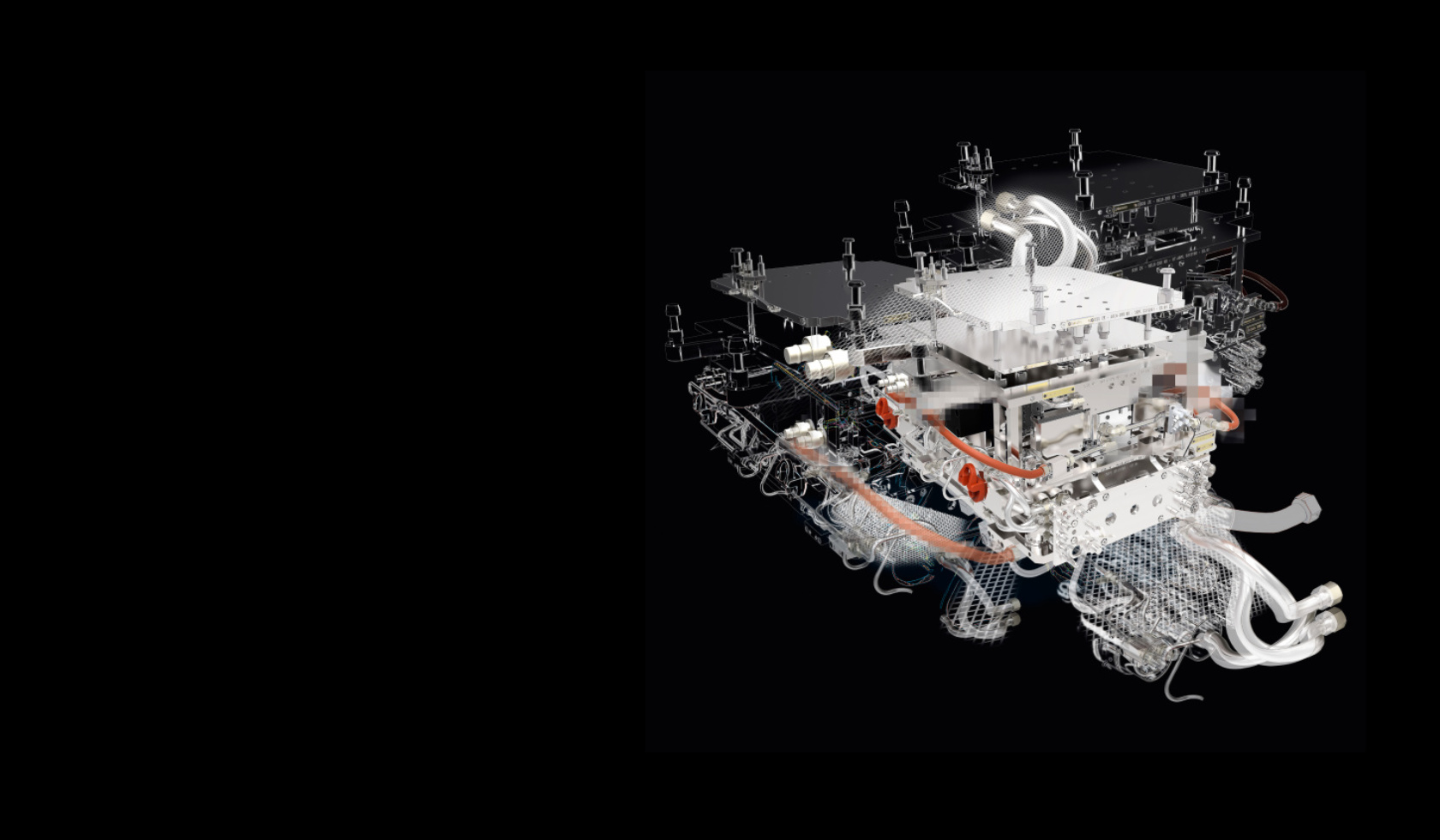

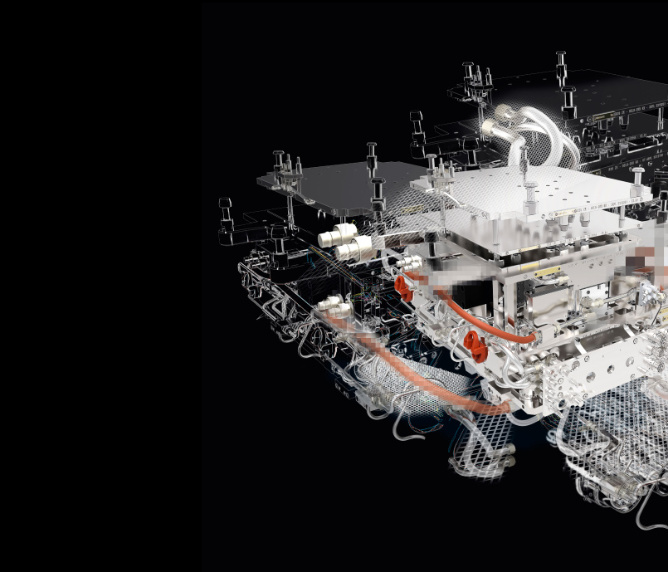

We use modern simulation tools. Such as core process simulations and casting simulations. Simulations of the tooling durability and simulations of the temperature in the cavity are used to optimize the tools and the general process. Even the casting parts are optimized by our experts.

In our own research projects we examine both various themes related to tool wear and also the temperature behaviour and diverse efficiency and cycle time optimisations using innovative tool engineering. Here we always have the potentials of digital networking in mind.