Currently, casting foundries mainly employ the polyurethane cold-box process to manufacture cores while inorganic core-making processes are gaining popularity. During the cold-box process, the reaction and the accelerated curing of the core are set off through the addition of a catalyst mixed with a carrier medium.

In inorganic core-making, however, this curing process is replaced by heating and purging with hot air, which causes water to evaporate and moisture to escape from the core box. It is a more complex and time-consuming process that is related to sand casting and curing, and is therefore subject to certain restrictions. This means that there are limitations on void spaces and geometry during inorganic core-making processes. Nevertheless, a compromise can be found between core filling and core curing.

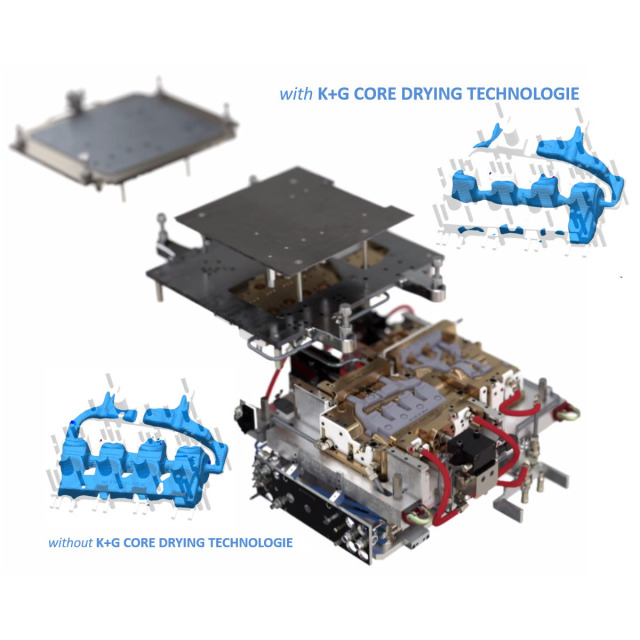

A process newly developed by KRÄMER+GREBE can be used in such cases for better core-drying performance. The Core-Drying Technology is integrated into the core box and can be fitted in new or existing moulding tools.

Come take a look for yourself and visit us at the booth of the company Laempe Mössner Sinto (Hall 17, Booth B40). On a Laempe LHL30 core shooter, you will be able to find a cold box equipped with our Core-Drying Technology. We will be delighted to explain to you in person the advantages of this innovative technology.

Contact:

KRÄMER+GREBE GmbH &Co. KG, Ludwig-Grebe-Straße 5, 35216 Biedenkopf, Germany

messe@kraemer-grebe.de – T +49 6461 80080