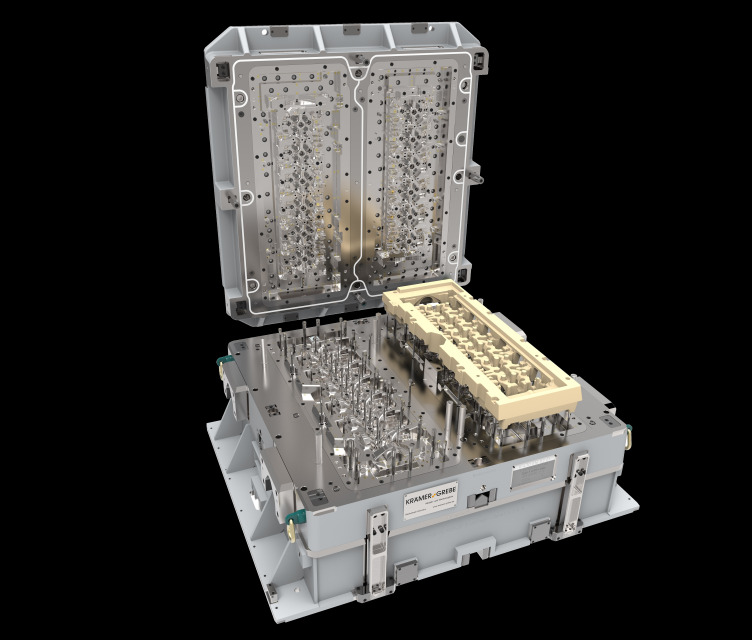

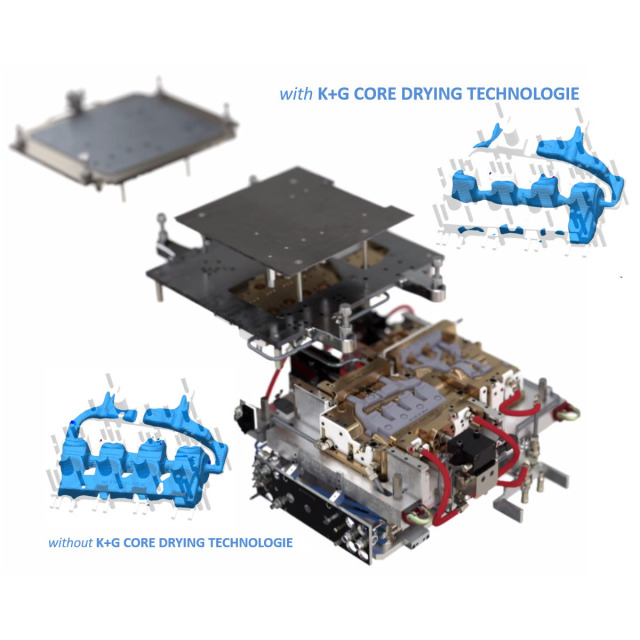

The quality of a cast product is significantly influenced by the corresponding injection moulding tools and core boxes. Due to the direct connection to the subsequent product, an optimal tool design is an essential factor in determining later success. Therefore, state-of-the-art simulation applications and 3D measurement technologies are used nowadays to aid in the engineering and manufacture of tools.

Especially in the development of cast products, it is not uncommon for the tool to be a critical factor when it comes to keeping the time to market as short as possible. At GIFA 2019, KRÄMER+GREBE will be presenting the latest methods for developing and manufacturing tools. The latest CAx tools, analysis methods, manufacturing technologies and digital technologies are used in everything from product idea development to optimisation loops to maintenance and lifetime extension.

Inform yourself at the GIFA on this interesting topic during a previous lecture of our specialists during the break-out session of the company GOM on the 26th and 27th of June – 14 p.m. in Hall 10, room 10.1 A.

During the trade fair, we will also be delighted if you would take the opportunity to visit our company premises in Biedenkopf-Wallau. Arrange an appointment today and come have a look at our revolutionary new development as well as our comprehensive service portfolio.

Contact:

KRÄMER+GREBE GmbH &Co. KG, Ludwig-Grebe-Straße 5, 35216 Biedenkopf, Germany

messe@kraemer-grebe.de – T +49 6461 80080