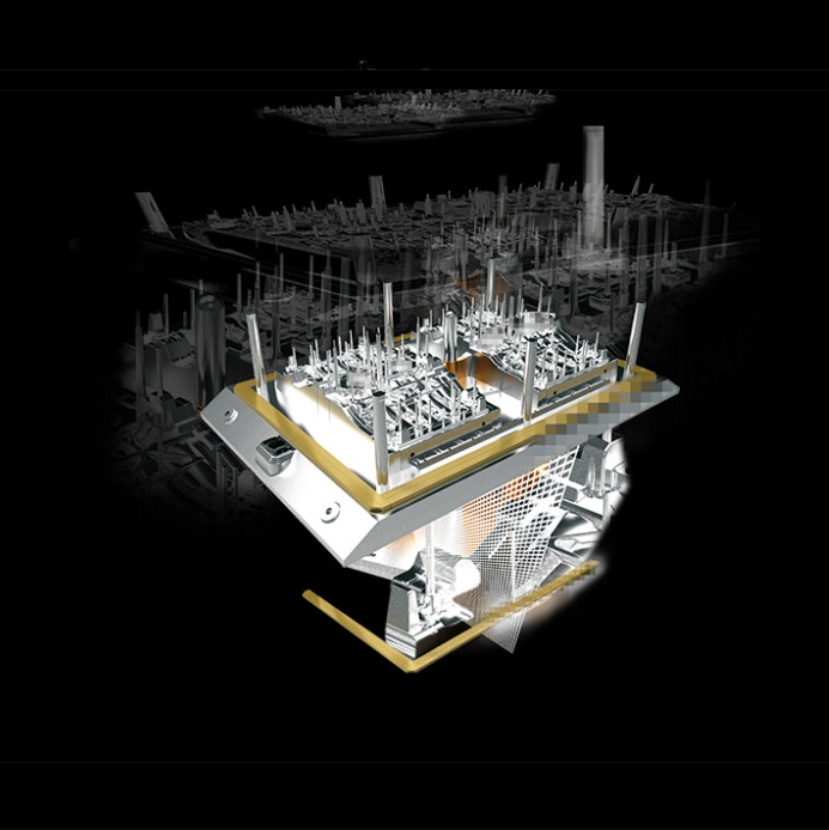

KRÄMER+GREBE designs and manufactures patterns and core box tooling for small and large production series in various materials, complete with all technical casting and venting details.

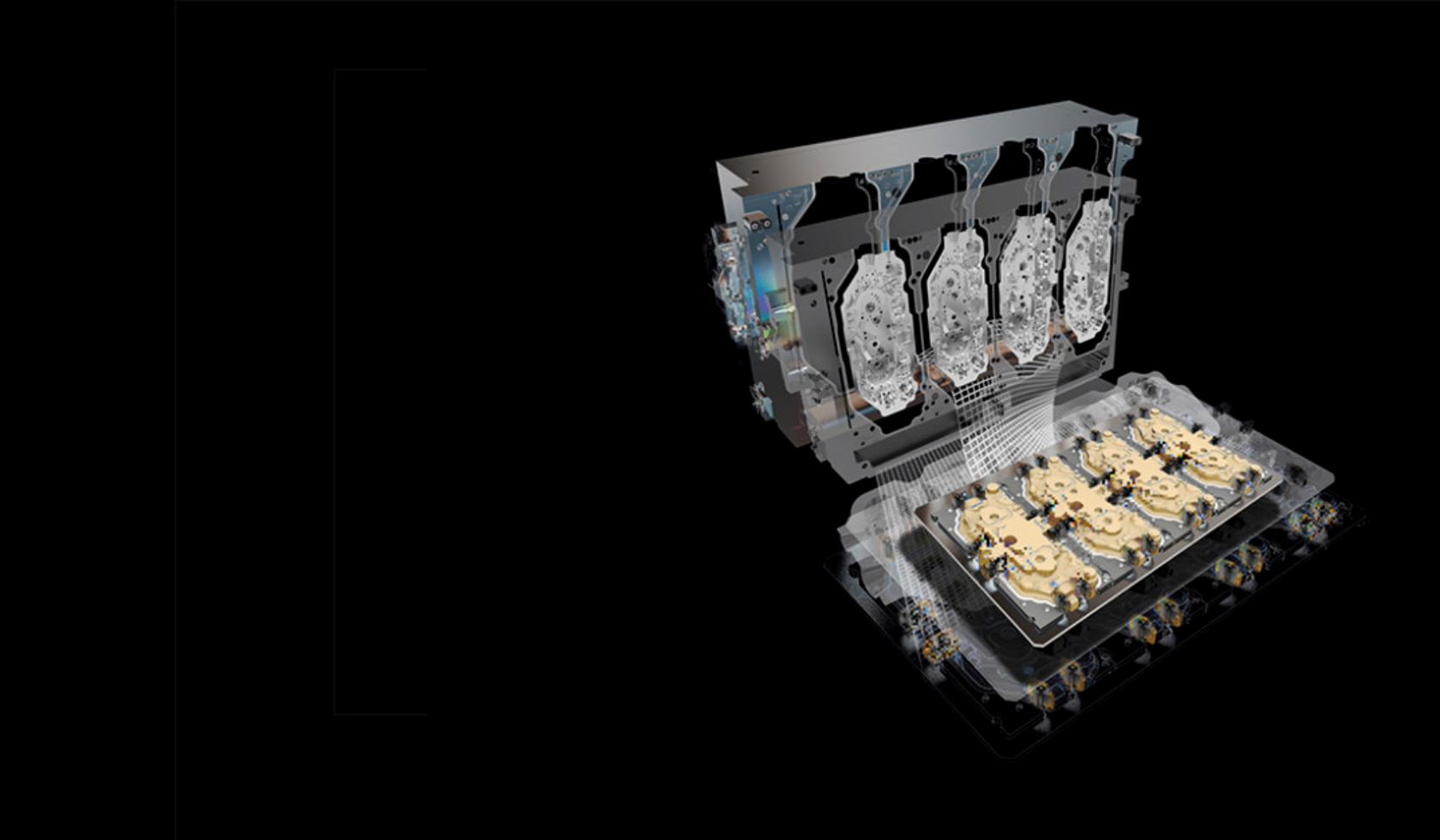

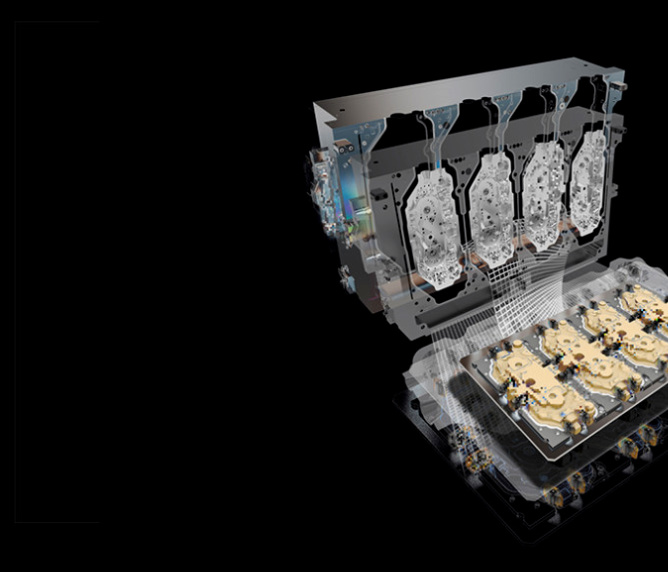

We offer complete tools for your core shooting machine suitable for all core production techniques.

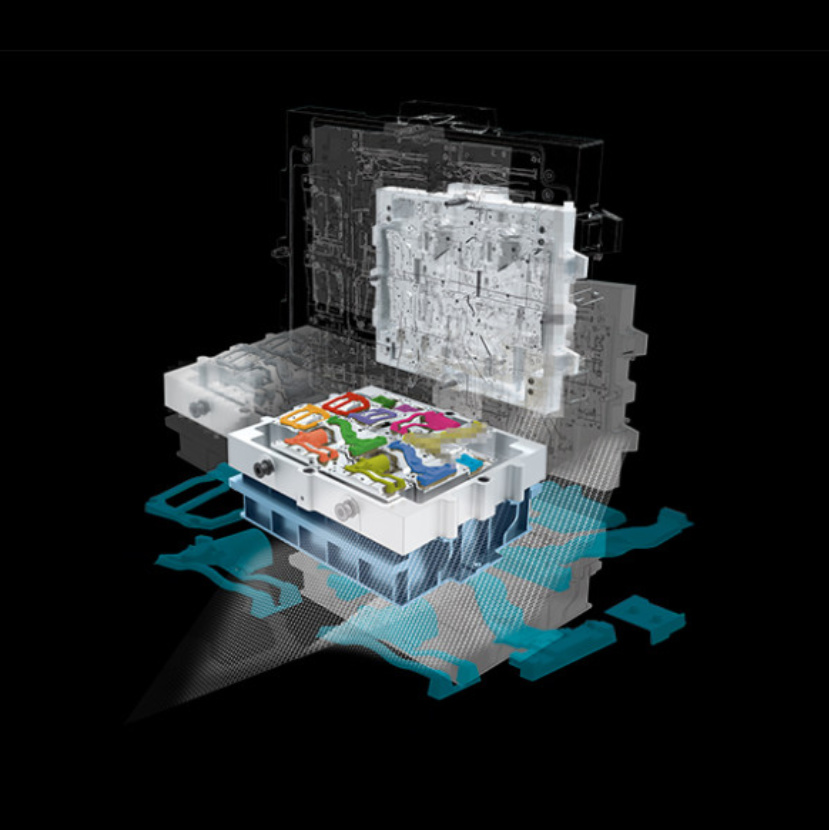

We produce individual, tailored tools to your exact requirements with all necessary accessories and to the highest standard of quality as core masks, for core package and green sand processes.

High degrees of freedom for complex geometries; excellent strength properties and high levels of dimensional accuracy characterise all manner of sand casting methods. Whether it is in a highly-automated high-volume process or for a small-scale premium series production, an intelligent tool concept paves the way for successful realisation. Not only do the tool specialists at KRÄMER+GREBE create the entire layout with core division and core mark definition, they are also completely familiar with sophisticated slider technologies, close-contour temperature control solutions, perfect machine adaptation and alternative material specifications in all areas. In addition, the tools are weight optimised and are designed to be maintenance and repair friendly. In addition to expert knowledge, KRÄMER+GREBE draws on the latest CAx technology, so as to achieve the best possible design for each moulding tool.