Competence and Equipment

People who think things through, apply themselves and are passionate about devising the best technical solution: these are our competent employees. Their competence makes KRÄMER+GREBE a market leader in tool solutions for all casting processes.

These high standards are maintained through regular in-house training. Our teams are experienced and coordinated; many of our employees spend their entire working lives with us. And this results in high identification with the tasks, an immense level of skill and exceptional productivity.

To ensure that our excellent employees can reach their maximum potential, we provide them with only the most modern equipment. Only in this way can we guarantee the outstanding quality of our products and services.

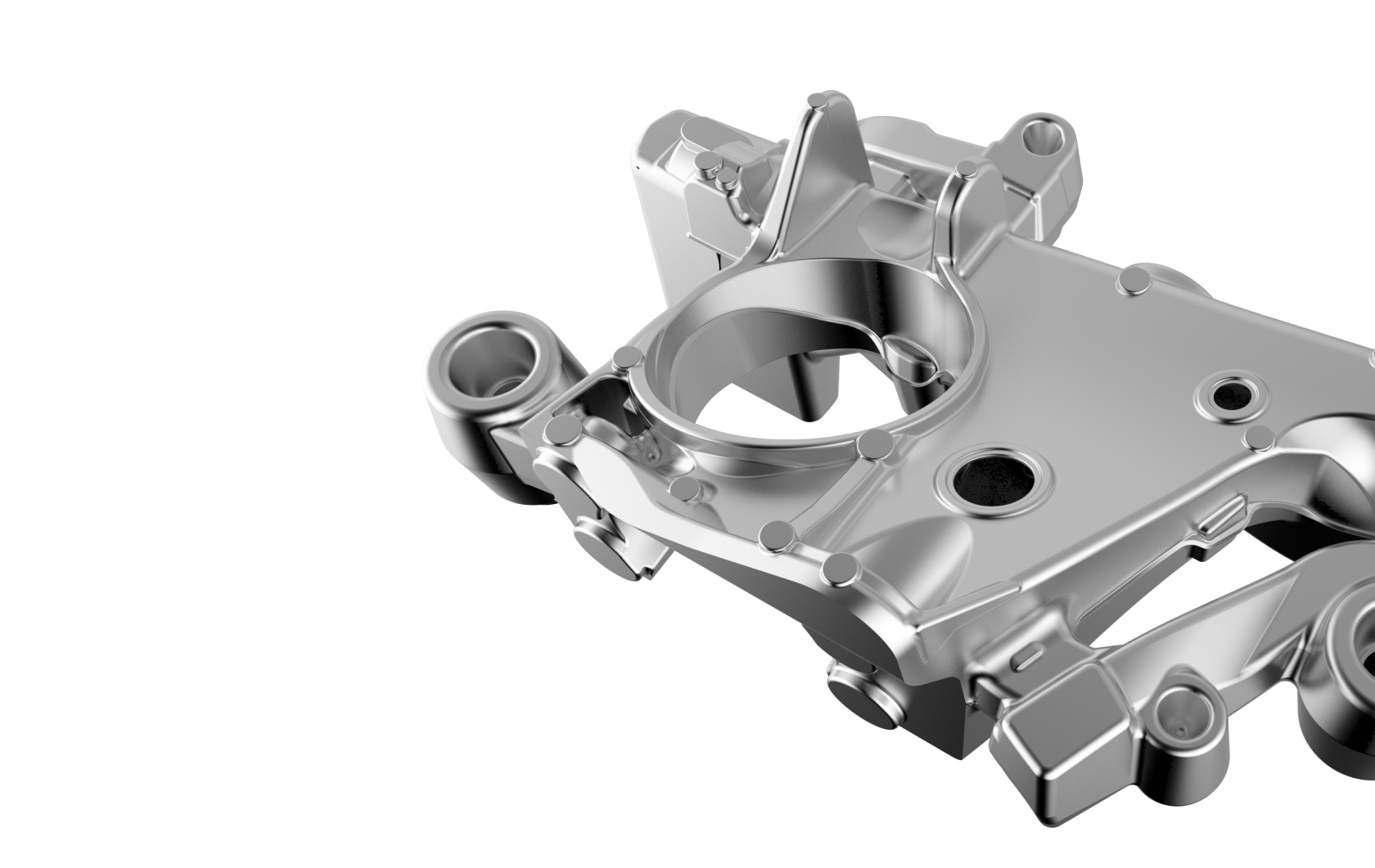

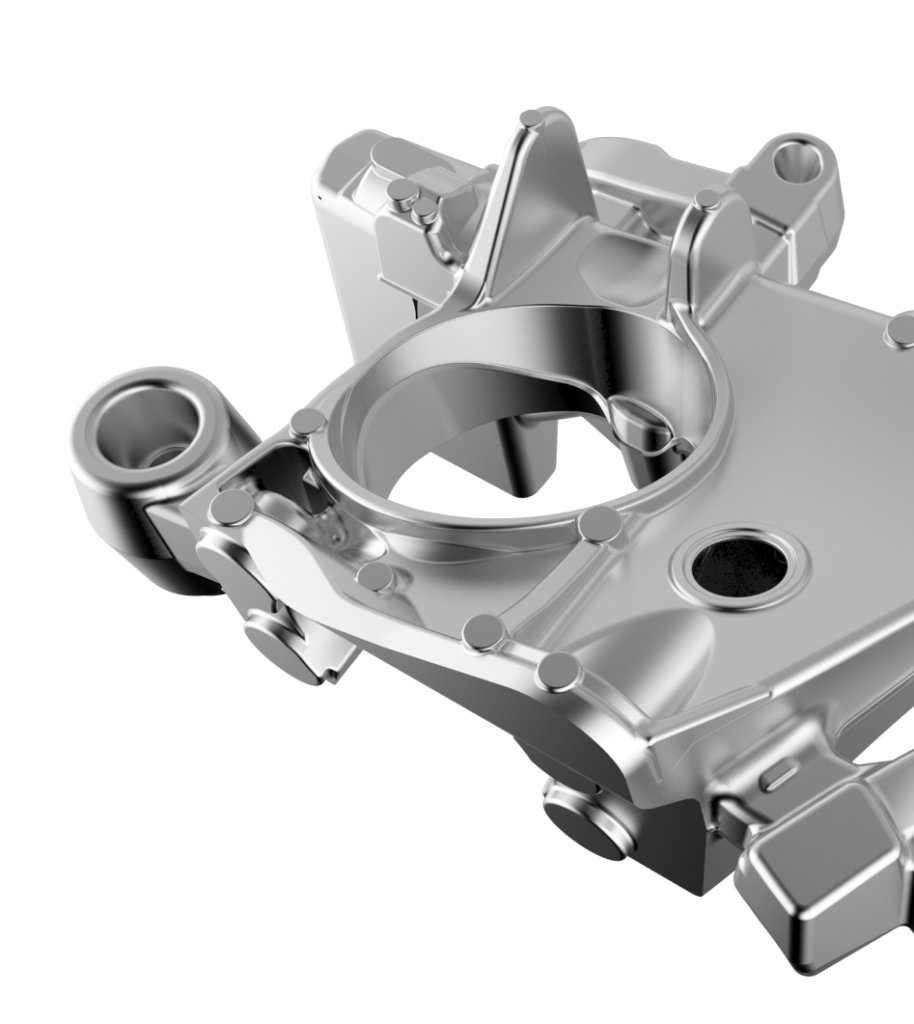

Construction

- CATIA, CREO, NX, SOLID WORKS, EUKLID

- Over 20 CAx stations

- Parametric, updatable tool design always to the latest modifications

Simulation

- Core process simulation

- Casting simulation

- Simulation of the temperature in the cavity

- Simulation of the tooling durability

Production and assembly

- Interactive, mobile project teams

- Tool specialists with advanced knowledge

- and proficiency in hydraulics, welding and electrics

- Digital process control and quality monitoring

- 3D CNC machining with tool changer

- 5-axis simultaneous milling

- Guideways up to 3 m, table loads up to 20 t

- CAM – CNC teams with rotation system and WOP

- Collision and machine data monitoring with call system

Quality assurance

- Quality assurance in climate-controlled measuring laboratory

- Optical GOM ATOS IIIE digitisation

- Reporting with POLYWORKS and visualisation using false-colour imaging

- 100% measurement of relevant areas

- Mobile CREAFORM laser scanner metrascan